Minuter is equipped with state-of-the-art testing technologies to ensure the quality of all turned metal parts we produce. These tools allow us to guarantee micrometric precision, full traceability, and absolute compliance with every technical specification.

Our metrology lab features advanced instruments for extremely accurate dimensional and geometric checks. It is the heart of Minuter’s quality system.

O-INSPECT ZEISS

The ZEISS O-INSPECT is a multisensor measuring machine that performs both contact and non-contact inspections. With CALYPSO software, we create custom, repeatable programs that deliver top-level precision in all measurements.

CONTOUR B & A

Two optical machines differing only in measurement range, ideal for inspecting the external profile of turned parts. Widely used both in initial part approval and in-process controls, thanks to their programmable and repeatable routines.

PROFILOMETER

Used for automatic profile measurements with dedicated stylus sensors, this instrument excels in setup stages for detecting radii, chamfers, and hard-to-measure dimensions that standard optical devices may not capture.

QUICK VISION

This CNC-controlled optical measuring machine combines a highly flexible zoom system with a high-precision color digital camera. Using the QVPAK software, we create highly accurate and repeatable measuring routines.

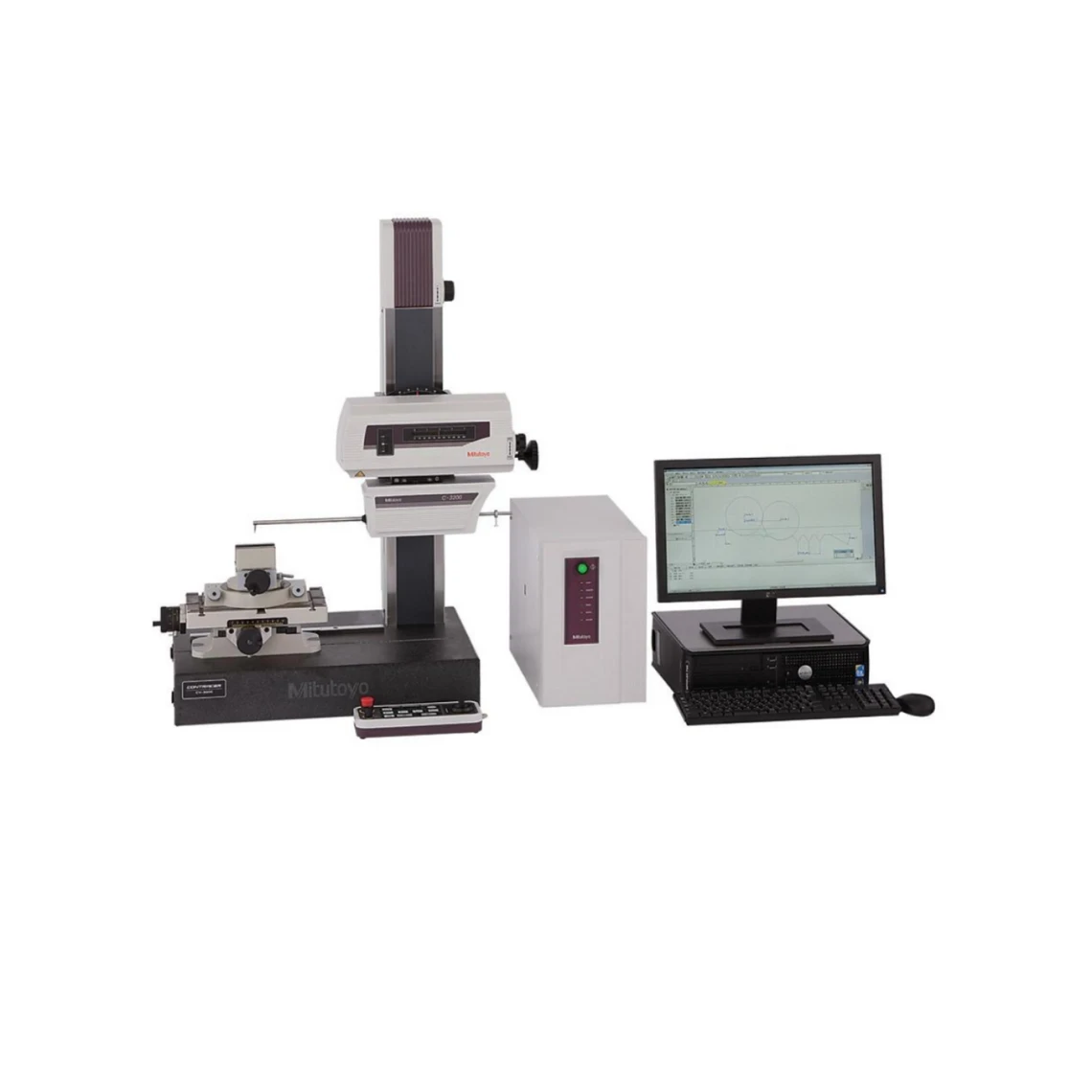

The Mitutoyo FORMTRACER CS-3300 is a compact and versatile instrument for combined contour and surface roughness measurement, ideal for quality control in industrial settings. It offers high precision, interchangeable modules, and an intuitive software for data analysis.