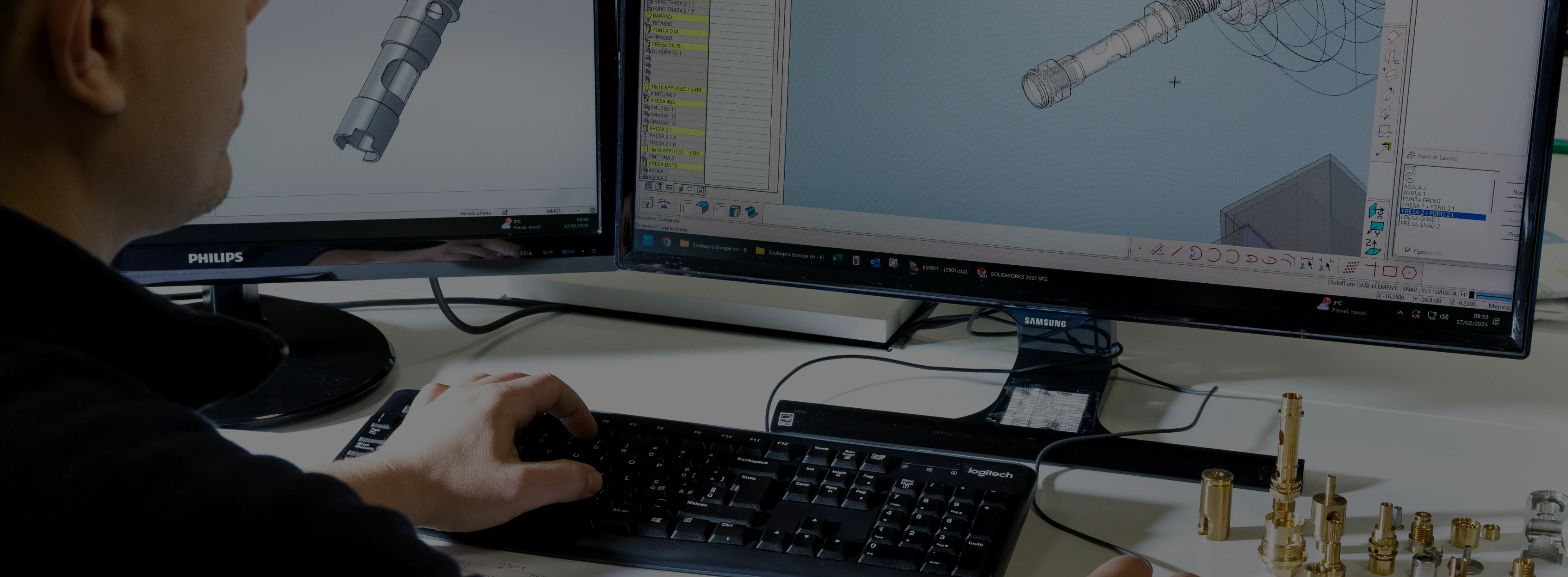

Our production process is the result of years of engineering work. We’ve developed an internal workflow that is fast, efficient, and extremely flexible.

Over the course of 30 years, we’ve developed extensive know-how that—combined with a cutting-edge machine park—enables us to produce high-precision parts, reduce downtime, and minimize errors. Every year, we invest in training and innovation to expand our expertise and refine our turning production processes. This leads to consistent product quality and faster delivery to meet the expectations of every client, with custom packaging ready for safe shipment.

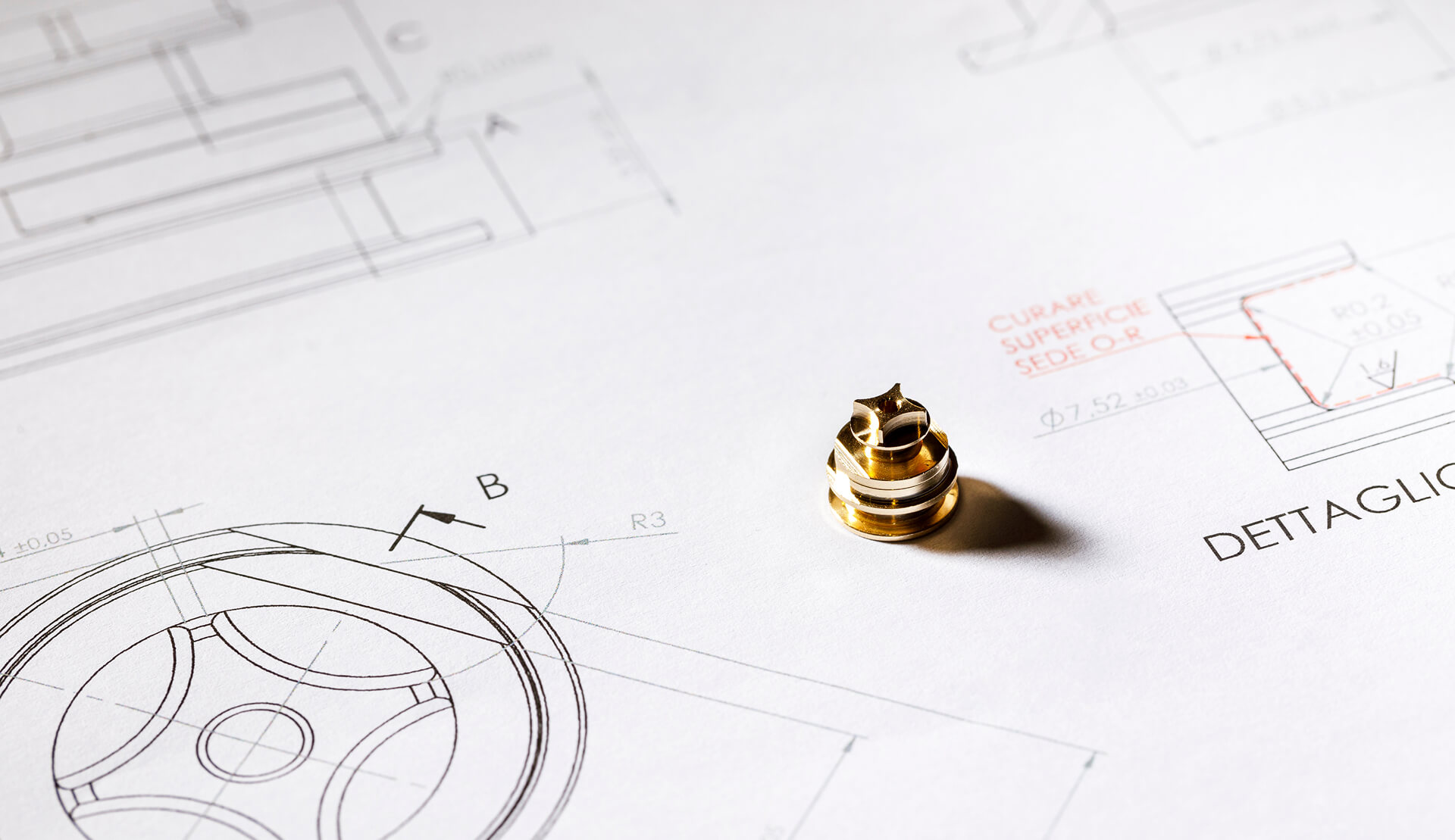

Our involvement starts well before production: we help turn ideas into fully optimized components, improving design and functionality while reducing costs and ensuring their efficiency.

We create prototypes and pre-series samples to validate each project before starting full-scale production, leaving nothing to chance. We also provide technical documentation required for certifications and approvals.

This is our core expertise: producing high-quality, tight-tolerance turned parts. We manufacture parts with diameters from 2 mm to 42 mm, using both sliding headstock (Swiss-type) and fixed headstock CNC lathes to deliver exceptional results.

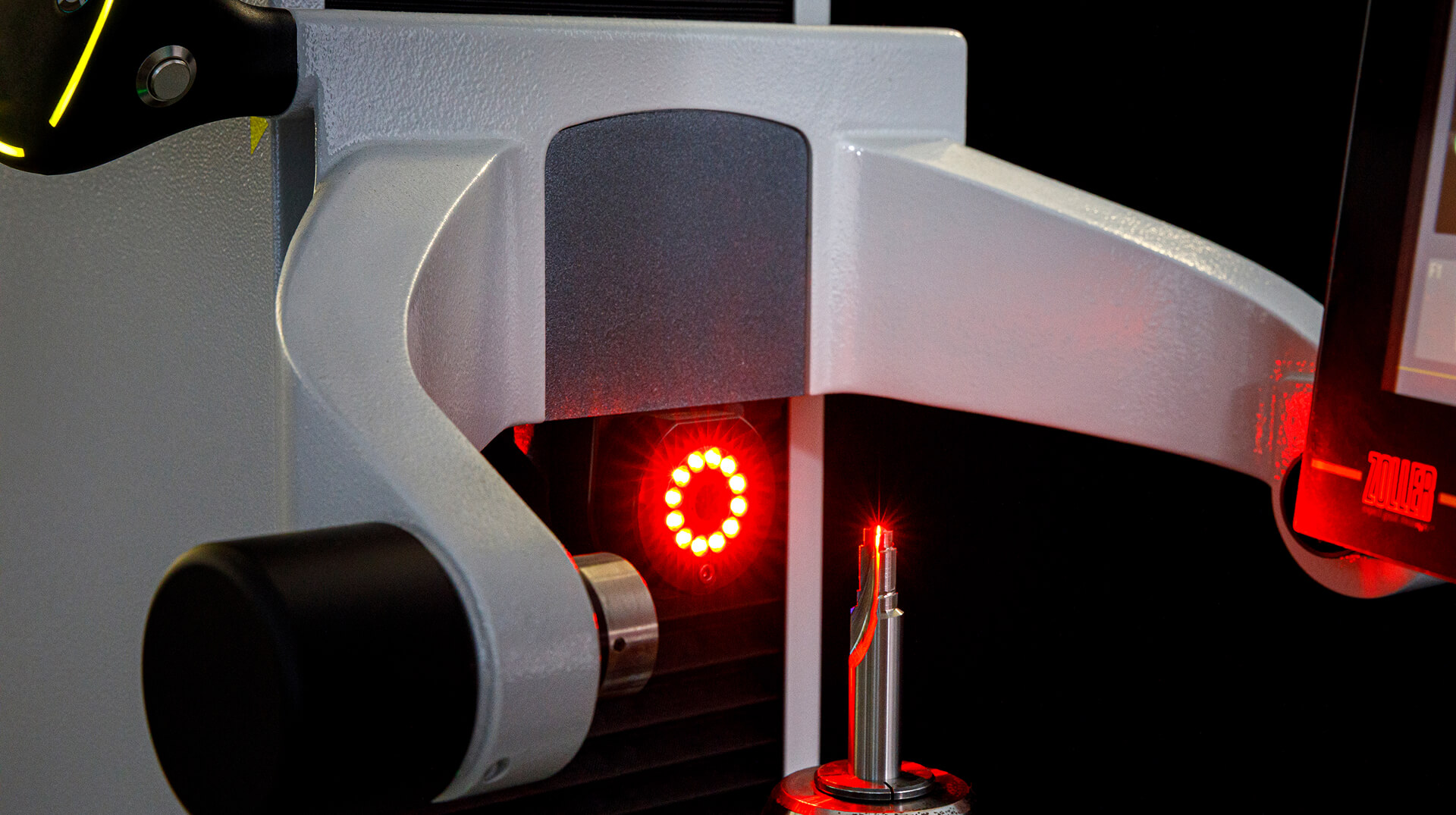

After the production, we monitor the quality through statistical controls and customized testing plans to ensure that every part meets the highest standards of precision and reliability.

Alongside production, we manage heat and surface treatments through a trusted network of qualified suppliers. We directly oversee their work and take full responsibility for the quality and success of the outsourced processes.

For applications requiring zero defect tolerance, we offer 100% inspection—manual or via selection machines—ensuring absolute compliance with customer specifications.

Product quality must be properly preserved. That’s why we design custom packaging for each component — to prevent any damage during handling and ensure that every item reaches its destination in perfect condition.