For each project and custom turned component, we use the most suitable machine and monitor production through Industry 4.0 systems.

By applying the right resources—both technical and human—during machining, we ensure optimal product performance while preventing additional costs caused by production mistakes or component malfunctions. Our turned parts stand for strength, safety, and durability.

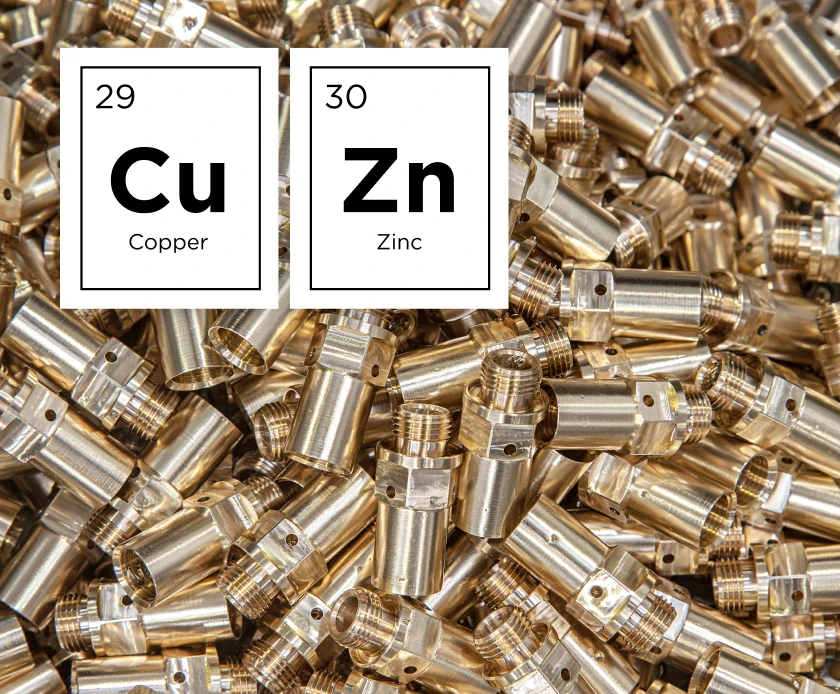

Including alloys, for parts up to 42 mm in diameter and 200 mm in length. We also manage surface treatments such as anodizing, coating, oxidation, and hardening.

For parts up to 35 mm in diameter and 200 mm in length. We can also handle magnetic annealing, passivation, etc.

We produce components up to 42 mm in diameter and 200 mm in length. We also coordinate processes like carbonitriding, zinc plating, nickel plating, copper plating, etc.

For parts up to 42 mm in diameter and 200 mm in length. We also manage treatments like nickel plating, chrome plating, copper plating, polishing, etc.

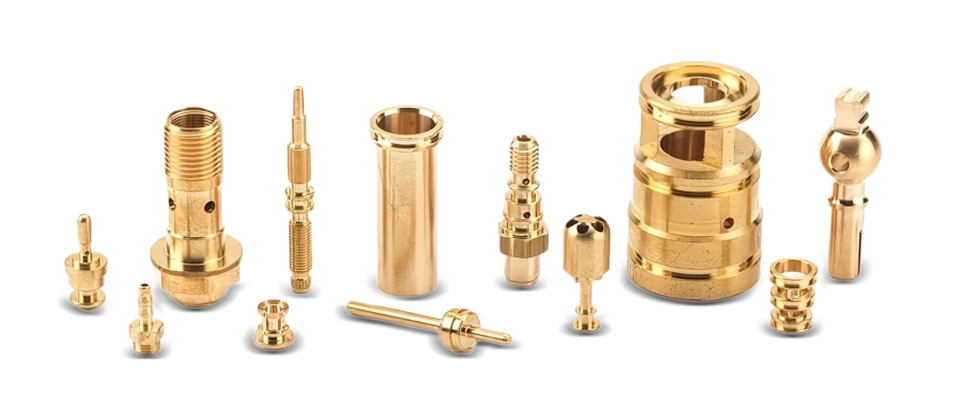

With both fixed-head and sliding-headstock lathes, we produce components suitable for a wide range of applications.

Learn moreWe believe that every customer and project deserves to be supported by the latest technologies for feasibility analysis. These renders showcase some examples of possible machining operations. Send us your drawings and let’s assess feasibility together using CAM simulations.