A vision driven by continuous growth, innovation, and uncompromising quality.

Minuter was founded with a clear goal: to manufacture precision turned parts tailored to the specific needs of each customer. From a small workshop where every piece was crafted by hand, we have evolved into a solid industrial reality, blending traditional craftsmanship with cutting-edge machinery and modern production processes.

With over 30 years of experience, we serve companies of all sizes with reliability and expertise.

We respond quickly and efficiently to every need, offering on-time delivery and fully customized solutions.

We earn our clients’ trust through commitment, precision, and attention to detail, building solid long-term partnerships.

Our skilled technical team is ready to handle any issue quickly and effectively.

At Minuter, each department works in synergy, sharing knowledge and objectives. This collaborative mindset is what sets us apart as a precision turning company.

Depending on the project, we can manage the entire production process or specific stages, always ensuring the same high quality standards.

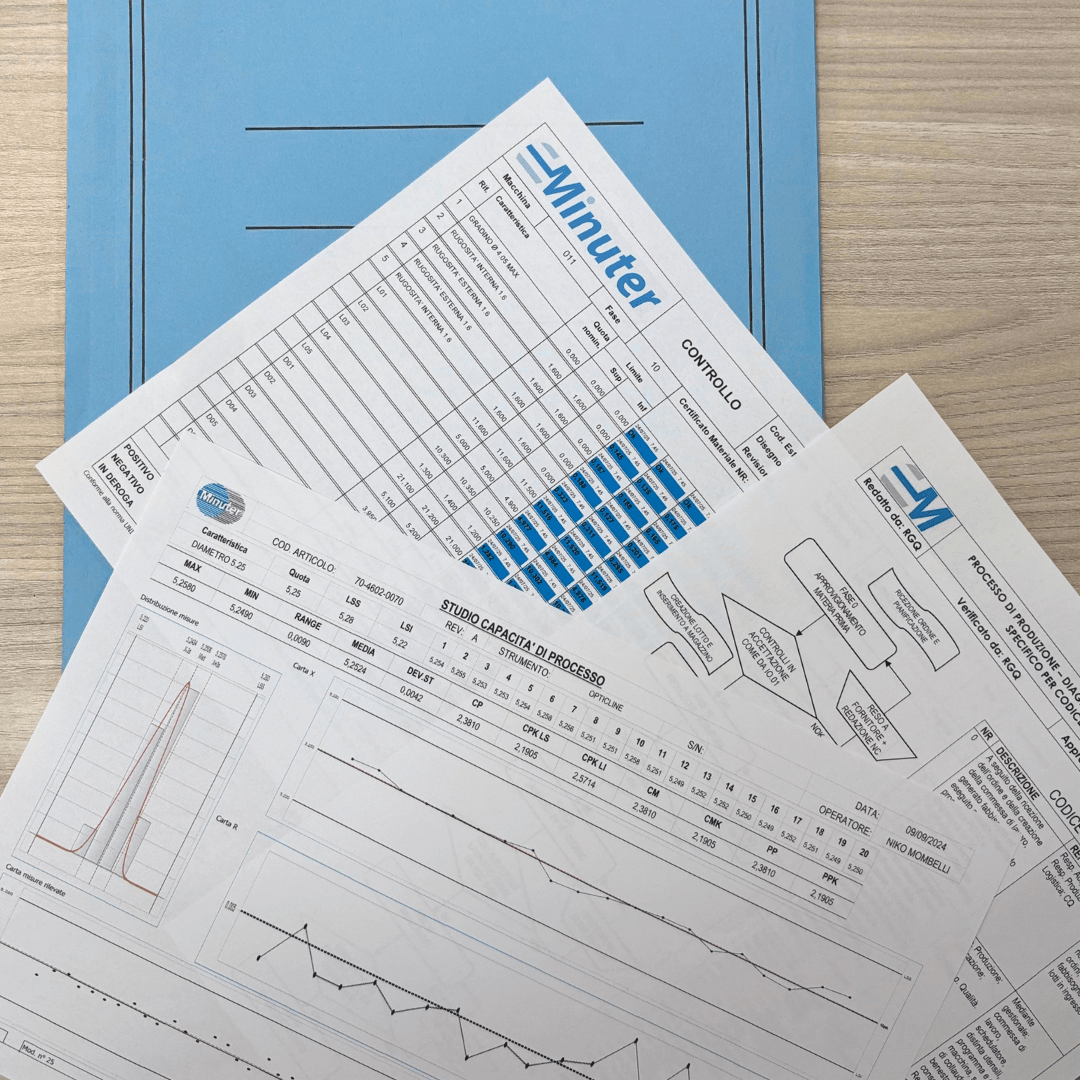

We provide comprehensive quality documentation, including PPAP and capability studies, ensuring full traceability, compliance, and reliability.

We co-design and review technical drawings to optimize each part.

We outsource nearly all types of heat and surface treatments, as well as small pre-assembled components.

Where possible, we use clean energy from our solar panels, as well as recyclable packaging and materials. Our green vision and concrete actions guide us toward a more sustainable future, in line with the ISO 14001 environmental standards.